Steve

+44 (0)7966 421369

Matthew

+44 (0)7866 791816

New Labelling Machinery Expert In Labelling Solutions

Automatic Labelling Machine Systems

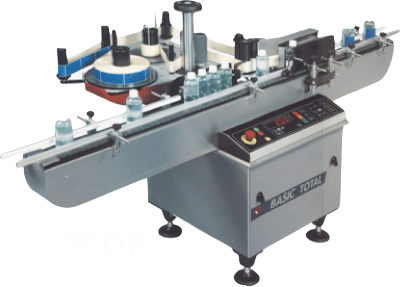

Automatic InLine Wraparound Labelling Machine Basic Total

Labelling Machinery Range

Finance

Want flexible paying options? S.C.Packaging has finance options that can help you, allowing you to make a low cost monthly payment to purchase your packaging machinery and equipment

Basic 100 Automat

Wraparound Labelling

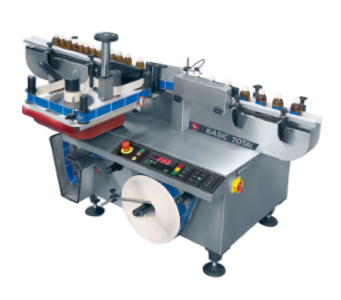

Basic 200 Automat

Wraparound Labelling

Basic 300 Automat

Wraparound Labelling

The Basic Total automatic labelling machine comprises of stainless steel base unit with enclosed electronics, intrinsic 2 metres slat conveyor, fully automatic side mounted labelling head, variable linked speed central motor drive and no language wipe clean digital control panel.

This machine comes in three distinct models: Basic 100, Basic 200 and Basic 300

Based on the success of the Basic 100 the Basic 300 has motorised bulk label spool with automatic tension control and end of reel sensor with opaque label detection as standard

Based on the success of the Basic 100 the Basic 200 has pneumatically operated three roller label applicator for optimum label placement and easily adjustable pre-dispensing and label positioning with graduated scale.

Wrap round labelling machines

-

•Easy to operate integrated controlled system with label counter and pre-set batch controls, keyboard and digital display.

-

•Suitable for a wide range of cylindrical labelling applications.

-

•Stepper motor: Fast and accurate labelling.

-

•Opaque label detection as standard.

-

•Pneumatically operated three roller label applicator for optimum label placement.

-

•Easily adjustable pre-dispensing and label positioning with graduated scale.

-

•Hygienic design using FDA approved materials.

-

•Small machine footprint.

Options Available:

-

•Scroll infeed spacing unit

-

•Infeed and outfeed rotary tables

-

•Hot foil or thermal transfer printing

-

•Low label warning

-

•Transparent label sensing

-

•Acoustic warning/error lights

-

•Label presence detection

-

•Barcode read/verification system

-

•Reject system

-

•Tri – Roller application

Basic 100 Automat Continues Labelling

Basic 200 Automat Three Roller Labelling

Basic 300 Automat In Line

Steve - 44 (0) 07966 421369

Matthew - 44 (0) 7866 791816

T - +44 (0) 1942 218476

Office

107 Gathurst Road

Orrell

Wigan

Lancashire

WN5 8QJ

S.C.Packaging Technology

email: